Do I have to empty the water from my spray booth before starting with Proco?

This is a very common question to which the answer is 'sometimes'. If your spray booth water contains a small amount of paint or sludge build-up and doesn't contain any chemicals other than your paint overspray, then there is a very good chance that we can start using Proco without having to change your booth water. If, however, the water has a large amount of sludge, within the tank, or contains chemicals other than your paint then we would recommend changing the booth water and starting the treatment with a tank containing fresh water.

The pipes & nozzles are always blocking, will using Proco reduce this?

Proco will certainly reduce blockages both within pipes, pumps and nozzles. Proco does three things to your booth water and the overspray within it; firstly, Proco stops the paint from sticking within the system, secondly Proco (when mixed with Proflo+) allows the paint to separate from the water so that it can be easily filtered and thirdly the paint is kept soft until removed. Blockages will be reduced and even eliminated as the paint is soft and will not stick.

The water pressure within my booth has reduced and it doesn't run very well. Will using Proco help?

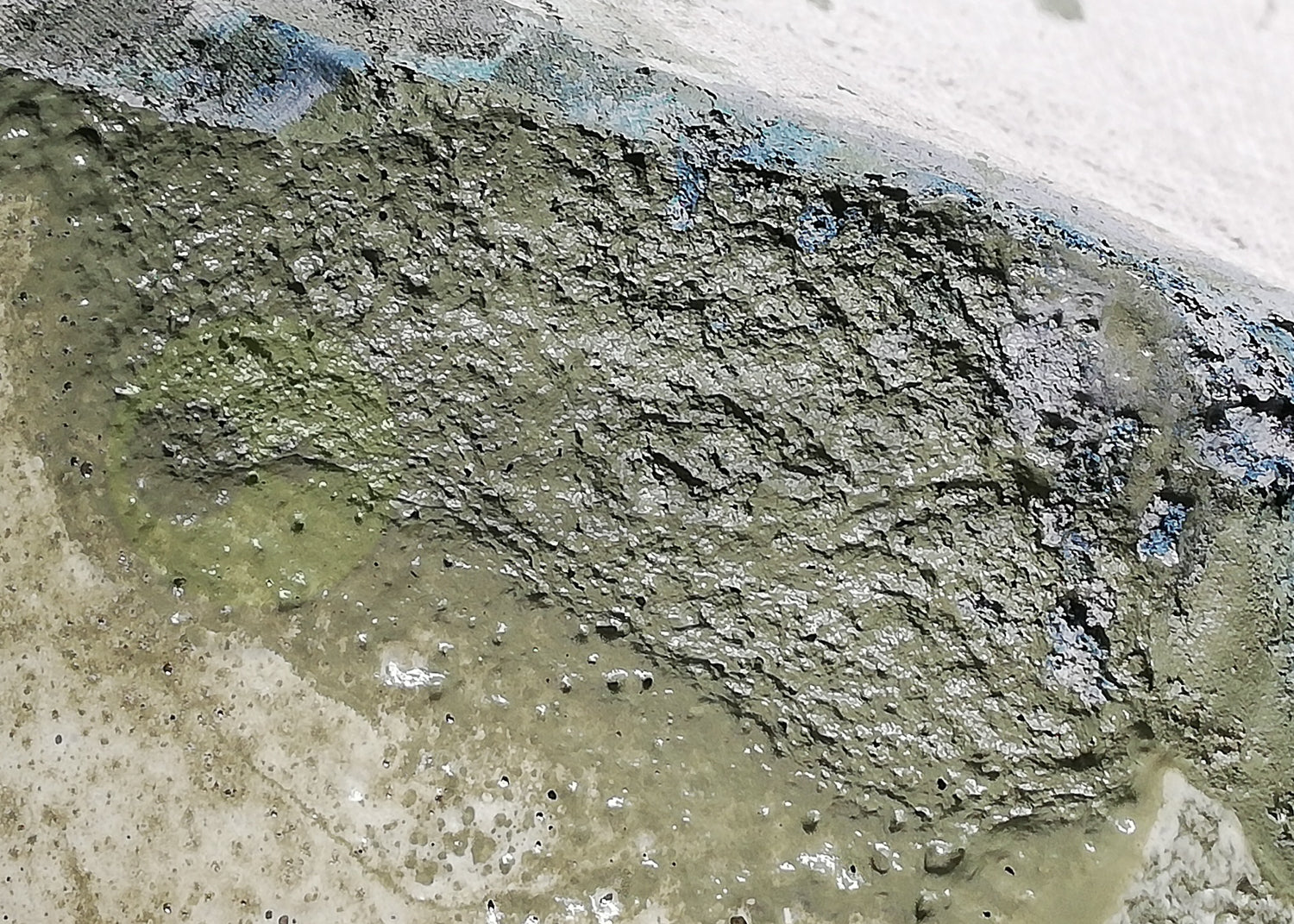

Our products can improve water pressure and the general operation of your booth in many ways. Proco will, over time, soften hard paint with your booth meaning that gradually the internal diameter will increase so the water flow will improve. This means that paint in hard to reach areas such as within pipes and pumps will be removed and the booth will slowly return to its original operational state. Providing that Proco is used correctly and as directed, you will not have new paint building-up and blocking your booth and, slowly, existing paint will be removed. However, the booth can be totally cleaned within a couple of days by using one of the products from our range of descalers. By adding this to your booth water, and allowing it to circulate for a few shifts, paint will be softened very quickly allowing to totally clean the booth within a few days.

Will using Proco stop my booth water from smelling so bad?

Proco contains an active biocide which will kill bacteria within the water. Basically, it is this bacteria that is causing the smells as the paint, within the water, starts to break-down. But, it is not the biocide alone that will stop the smell as the Proco system will allow you to remove all of the paint build-up in the first place. Therefore, if you are removing the paint then there will not be any in the water to start breaking down which means no smells.

Do I have to use Proflo+?

Proco and Proflo+ are designed to work in conjunction with each other to keep your spray booth water clean and clear of paint build-up however you don't have to use Proflo+ if you would prefer not to but this will mean that you will be unable to successfully remove all of the paint from your system. As we have said, Proco & Proflo+ do different jobs; Proco will keep paint soft within your booth and will allow it to separate from the booth water, Proflo+ pulls the separated particles together and helps them to float so that they can be removed. If you decide not to use Proflo+ then the paint will be separated, it will be soft and will be less inclined to stick within pipes and nozzles but it will not float therefore it will slowly collect on the floor of the water tank. This is fine for some installations and for some owners but for the majority of our customers Proflo+ is used.